PRODUCT

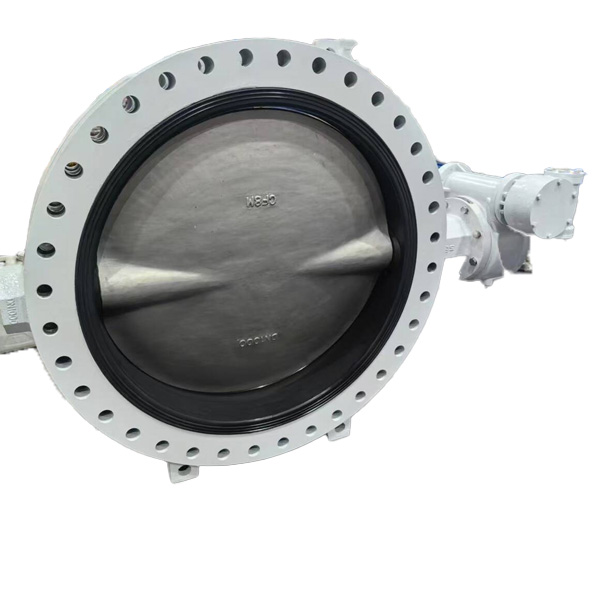

Seawater desalination butterfly valve

Designed as Standard : GB/T12238-2008; AWWA C504, API 609

Face to Face : 100-GB/T1221-2005-J9;

150-800-JISB2002 (Ship1 2 3 Series)

900-2800- Japan(Tomoe Standard )

Flange as Standard : GB/T17241.6 ; DIN2632/2633;BS4504;

JIS-B2220 ; ASME B16.5(150LB)

Test Standard : API598

Material:

|

No. |

Part Name |

Material |

|

1 |

Body |

/Stainless Steel/Cast Iron/Ductile Iron/ Al-Bronze |

|

2 |

Disc |

Al-Bronze/CF8M/Ductile iron+epoxy /WCB/Halar coating |

|

3 |

Seat |

EPDM/PTFE/Buna/NBR/Hypalon |

|

4 |

Stem |

Carbon Steel/Stainless Stee304/SS410 |

|

5 |

Bushing |

PTFE/Lubricating |

|

6 |

O ring |

EPDM/PEFE/Buna/NBR/Hypalon |

|

|

|

|

Features:

1. The butterfly plate has been optimized to effectively increase the flow area of the butterfly valve and reduce fluid resistance;

2. According to different working conditions, the appropriate butterfly plate sealing ring can be selected to ensure that the valve will not leak internally within one maintenance cycle;

3. The valve body, butterfly plate, pressure ring and other components are made of carbon steel, which effectively reduces manufacturing costs. All parts in contact with the medium are sprayed with wear-resistant and corrosion-resistant coatings such as ceramics, which can increase the valve's ability to resist seawater corrosion and erosion;

4. The valve sleeve is made of duplex stainless steel and has an interference fit with the shaft hole on the valve body, effectively preventing seawater from corroding the shaft hole of the valve body;

5. There is a retaining ring between the valve stem and the shaft sleeve, which prevents seawater from seeping into the gap between the valve stem and the shaft sleeve, eliminating seawater corrosion on the valve stem and sleeve. At the same time, it prevents mud and sand in seawater from seeping into the gap between the valve stem and the shaft sleeve, causing the valve stem and the shaft sleeve to bite, effectively increasing the service life of the valve;

6. The valve seat sealing surface is welded with duplex stainless steel, which is wear-resistant and erosion-resistant, effectively improving the reliability of valve sealing;