PRODUCT

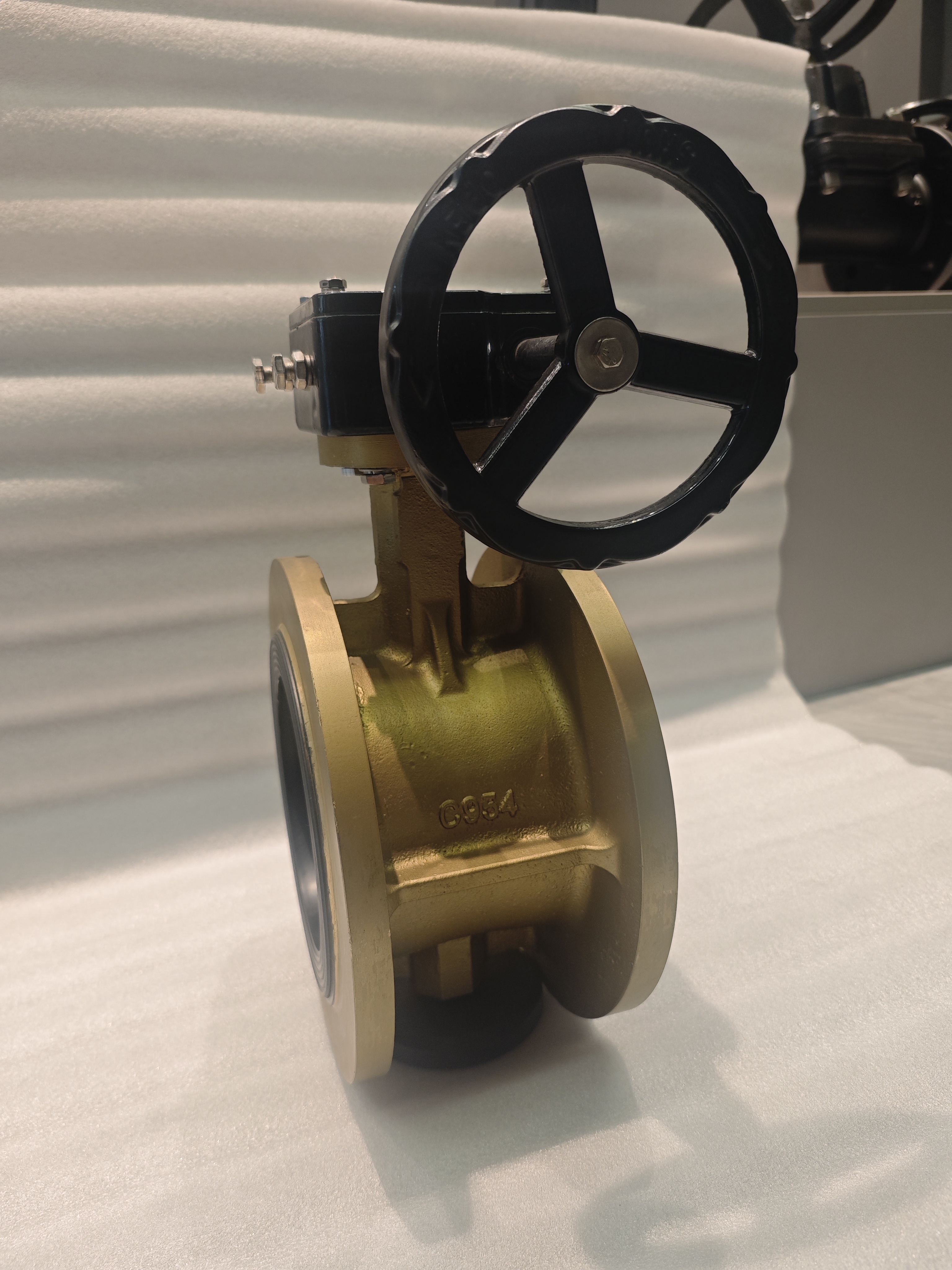

wafer type seawater desalination butterfly valve

Size: DN40-DN1200

Pressure: PN10/PN16/25/150LB

Design standard : API609 ,BS EN593.MSS SP-67 BS5155

Standard: Flange: DIN3202, DIN2501 PN10/PN16

Face to face:API609, ISO5752,BS EN558, BS5155,

MS SP-67,DIN3202

Test Standard: API598

Wafer type seawater desalination butterfly valve

Material:

|

No. |

Part Name |

Material |

|

1 |

Body |

bronze |

|

2 |

Disc |

Al-Bronze/CF8M/CF8 |

|

3 |

Seat |

EPDM/PTFE/Buna/NBR/Hypalon/Viton |

|

4 |

Stem |

SS410/SS304/SS316 |

|

5 |

Bushing |

PTFE/Lubricating |

|

6 |

O ring |

EPDM/PEFE/Buna/NBR/Hypalon |

|

7 |

Pin |

without pin

|

Features:

bronze butterfly valve offer excellent corrosion resistance, resisting attack by acids, alkalis, and other chemicals, ensuring long-term reliable operation in relatively harsh operating environments, such as those found in the chemical, petroleum, and pharmaceutical industries. Copper valves also effectively prevent rust and corrosion, ensuring water quality remains uncontaminated, making them suitable for small water supply systems with high water quality requirements.

bronze butterfly valve thermal expansion coefficient closely matches the temperature fluctuations of the fluid, reducing thermal stress on the valve during temperature fluctuations and extending its service life. Furthermore, copper's high toughness allows it to deform under external forces such as impact and extrusion without cracking, making it suitable for applications requiring resistance to external forces.