PRODUCT

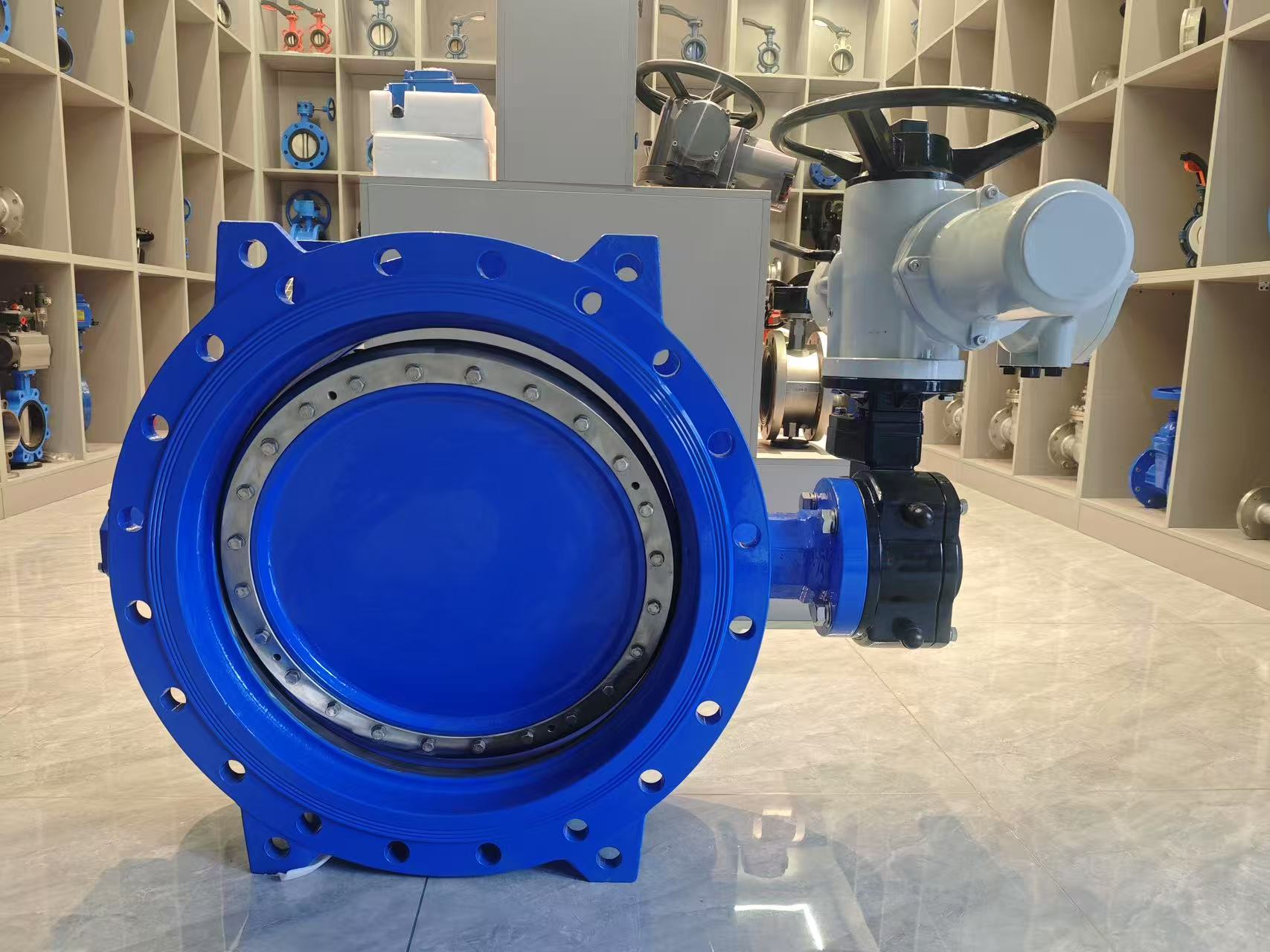

electric double eccentric butterfly valve

:

SIZE : DN100-1200

Pressure :150LB /PN10/16

Flanged End : ASME B16.5/ ASME B16.47-150LB

Face to Face: API609/ ASME B16.10/AWWA C504

Top Flange : ISO5211

Tightness :ISO5208/API598/EN1266-1

Electric double eccentric butterfly valve Material

|

No. |

Part Name |

Material |

|

1 |

Body |

GGG50 | A536 | A395 | WCB | CF8 (304) | CF8M (316) |

|

2 |

Disc |

GGG50 | A536 | A395 | WCB | CF8 (304) | CF8M (316) |

|

3 |

Seat |

Buna-N(NBR) | EPDM | Nature Rubber | Silicon Rubber | VITON |

|

4 |

Stem |

AISI 304 | AISI 420(2Cr13) | 1.4462 | Monel | 17-4PH |

|

5 |

Bushing |

PTFE/Lubricating |

Product Overview

This series double eccentric butterfly valves is suitable for shutting off and regulating medium flow in long-distance water pipelines, tap water systems, power plants, metallurgy, petrochemical, and other industrial pipelines.

Eccentric butterfly valve Structure and Technical Performance

1. The circular disc design offers excellent resistance to internal tension, high disc rigidity, a large flow area, and low flow resistance.

2. The stem and body utilize V-type packing for tight sealing and adjustable spring force. The seal can be replaced online without disassembling the transmission, resolving stem leakage issues.

3. It can replace eccentric hemispherical valves, hard-seal butterfly valves, and high-performance butterfly valves. The integrated bracket provides strong rigidity, stable transmission, and precise opening and closing positions.

4. The valve seat features a replaceable, movable structure made of high-quality polytetrafluoroethylene and carbon fiber. The seal is resistant to wear, aging, and deformation. The movable valve seat ensures a bidirectional seal with zero leakage. The double eccentric structure ensures that the valve disc releases from the seat instantly upon opening, and the disc sealing surface only contacts the seat when closed at 90°, extending the valve seat life and reducing valve operating torque.

5. The design meets national standard diameter requirements while combining the advantages of eccentric hemispherical valves and butterfly valves. Compared to butterfly valves, it offers a larger flow area, lower flow resistance, and greater energy efficiency. The secondary eccentric valve has low opening and closing torque and excellent sealing performance. Self-lubricating bearings reduce valve operating torque. The disc sealing surface is welded with high-hardness alloy steel for minimal wear, high temperature resistance, wear resistance, and bidirectional pressure, with a service life of up to 30 years.

6. The double eccentric butterfly valve seat can also be made of pure stainless steel, while the disc sealing surface is welded with high-hardness alloy steel, achieving a bidirectional, zero-leakage metal seal.

7. The disc pivots between 0° and 90°, with 0° indicating fully closed and 90° indicating fully open. The ball butterfly valve features a simple structure, compact size, and light weight, offering fast opening and closing times, low flow resistance, adjustable flow, and easy operation.

8. double eccentric butterfly valve Electric actuators facilitate remote control of projects.